What is dead stock and how to eliminate it

A CFO of a wholesaler recently described dead stock as piles of cash in the corner of a warehouse that she can’t access. And, in many ways, she’s not wrong. Dead stock is unsold products in storage or returned from retailers. It reduces the cash flow you need to buy revenue-generating stock and takes up valuable warehouse space that profitable products could use. Dead stock inventory also increases carrying costs, tying up resources in excess inventory that no longer matches customer demand.

Effective inventory control and demand forecasting reduce dead stock and improve inventory turnover. This blog examines how to minimize dead stock and retrieve cash back from obsolete stock.

What does dead stock mean for your business

Dead stock is inventory that sits unsold for an extended period, often due to changing customer demand, poor sales or seasonal shifts. Businesses across all industries face this problem, which can have a significant financial impact.

Here are some examples of dead stock:

-

A fashion retailer who over-ordered winter coats will struggle to sell them when summer arrives and will have to discount heavily or store them until next year.

-

A wholesaler of technology accessories will find themselves with old phone cases when a new model is released, and they can’t sell them at full price.

Identifying the causes of dead stock

Several factors contribute to dead stock – the end of a season or product life cycle, over-ordering, poor sales or a new competitor coming in. Sometimes, long lead times and misaligned reorder points can also cause overstocking. Seasonal items can quickly become obsolete if not appropriately managed, while not tracking SKU performance can mean an accumulation of excess stock.

To identify the causes of dead stock in your business, start by analyzing inventory levels based on investment value, shelf life and turnover rates. Then use sales data and an inventory management system to refine order quantities. Understanding why stock becomes obsolete helps you to tailor your purchasing strategy to prevent future dead stock.

Monitor and prevent future dead stock

Many businesses have dead stock because of poor inventory management purchasing practices, and a lack of real-time data. Investing in inventory management software with real-time tracking will allow you to better monitor stock levels, demand fluctuations and reorder points.

A business intelligence tool like Phocas lets you go beyond reports. Daily updates allow you to track inventory metrics like inventory turnover, stock-to-purchase ratio, slow-moving stock, and GMROI (Gross Margin Return on Investment) by product category. Then, you can adjust your marketing, optimize inventory control, and prevent overstocking accordingly.

Clear out dead stock from your warehouse

Even with the best inventory management systems, some stock will still be hard to sell. Here’s how to get rid of dead stock items and get some of your money back:

-

Return to supplier: Negotiate flexible return agreements with suppliers when setting up new contracts. Use your inventory software to track return deadlines and avoid write-offs.

-

Product bundling: Pair slow-moving products with high-demand items to create sales. For example, if a particular SKU is not selling, bundle it as a free gift with popular or new products to make it more attractive.

-

Clearance sales and liquidation: Consider clearance sales or liquidation to get your money back when stock doesn't sell. Deep discounts can move excess inventory fast and free up space. See our whitepaper on cross-selling and upselling for more on this.

-

Leverage marketing: Promote overstocked products through targeted sales campaigns, email marketing, or flash sales to increase demand and reduce inventory.

-

Donation and write-offs: If stock is truly unsellable, consider donating to charity in exchange for tax deductions. It’s not ideal, but a write-off may be the best option for obsolete stock.

Improve forecasting to minimize risk

One of the best ways to prevent dead stock is through forecasting. Businesses can forecast stock requirements and optimize order quantities by analyzing past sales data, seasonality trends, and customer demand patterns. Incorporating historical data and real-time analytics allows businesses to make data-driven decisions on inventory control, reducing the likelihood of over-ordering.

In addition, having enough safety stock prevents stockouts and ensures excess inventory doesn’t build up. Setting reorder points and lead times helps to strike a balance between having enough stock to meet customer demand – and not storing unnecessary inventory.

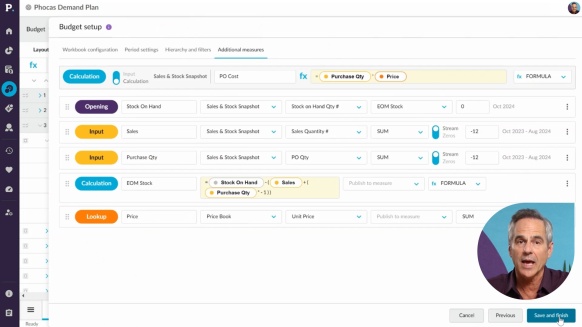

Phocas can help you create a demand plan that seamlessly integrates sales forecasts and purchasing data – making sure you’ve always got the right stock amount on hand. Phocas connects directly to your purchasing, stock and sales database to create your demand plan. You can forecast stock levels by supplier and product class and go down to the SKU level.

Minimize dead stock and increase profit

With the right business intelligence software, demand forecasting strategies, and inventory control measures, businesses can minimize dead stock and improve profit margins. Dead stock isn’t just an inconvenience—it represents an opportunity cost that affects the bottom line. By proactively monitoring inventory levels, leveraging product bundling, and using data-driven marketing efforts, companies can turn stagnant stock into profit and maintain a healthy, efficient supply chain.

Empowering businesses with intuitive data analytics, driving informed decisions for growth and profitability. We make people feel good about data.

Related blog posts

Inventory management is a tight-rope balancing act. Ordering too much leaves you with excess stock tying up capital and warehouse space. Ordering too little puts you at risk of running out of stock, leading to stockouts, missed sales, and frustrated customers. Bad inventory forecasting means storage fees, excess inventory, waste from unsold goods, and operational inefficiencies that eat into profits.

Read more

Tariffs are here. Whether you're in manufacturing, distribution or retail, it's important to understand how importing from affected countries such as Canada, Mexico or China or chosing local production, can affect your bottom line. We want to encourage you to scenario plan now not retrospectively.

Read more

Finance professionals in distribution businesses face a persistent challenge. That is to effectively blend operational and financial data to gain a complete picture of company performance. Traditional financial ratios often exist in isolation, making it difficult to assess the broader impact of operational decisions on financial outcomes.

Read more

Managing sales in a distribution business without measuring key performance indicators (KPIs) is like maintaining your home without tools or a schedule. You don’t notice a leak until the damage is severe. Instead of making progress, you waste time searching for the right tools or calling an expert for simple fixes. Without the right KPIs, inefficiencies can go unnoticed, leading to cashflow issues and lost sales.

Read moreBrowse by category

Get a demo

Get a demo Find out how our platform gives you the visibility you need to get more done.

Get your demo today