Navigate manufacturing challenges

From fluctuating tariffs to rising energy costs and labor shortages, manufacturing is a complex and fast-moving industry. Mid-market manufacturers must operate with both speed and precision to protect profitability while navigating supply chain instability, shifting demand and digital transformation.

Phocas provides a unified, cloud-based Business Intelligence (BI) and Financial Planning & Analytics (FP&A) platform that gives manufacturers end-to-end visibility and control over how they manage and plan manufacturing operations – whether they're reshoring or managing multi-entity ERP environments.

Manufacturer challenges

Tech stack

consolidation

Tariff & supply

chain uncertainty

Rising costs &

margin pressure

Labour shortages &

production efficiency

Evolving products & customer demand

Navigating

AI hype

From gut feel to data-driven strategy

"If we're making business decisions on where to invest – for instance, engineering, R&D, stock holdings – you need to be looking at the trends to make those decisions. You can't afford to do guesswork when it's involving millions of dollars worth of stock or marketing. I can ask it any question, and I get an answer really, really fast."

– Ross Ollington, National Sales & Marketing Manager at TJM

Manufacturing tech stack consolidation

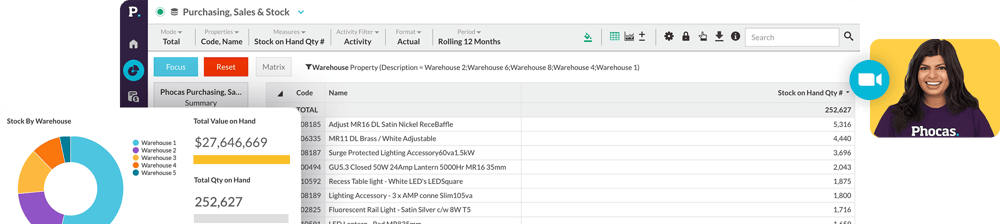

Many mid-market manufacturing companies struggle with fragmented systems – legacy ERP software (or managing multiple ERPs), production planning tools, disconnected spreadsheets and quality control databases that don't communicate effectively.

Phocas unifies manufacturing data ecosystems:

- Multi-system integration: Consolidate production metrics, inventory levels and financial data from your ERPs, MES and QMS systems into a single source of truth.

- Self-service advanced analytics: Enable production managers to build custom reports on scrap rates, overall equipment effectiveness and product quality without IT support.

- AI-assisted BI: Ask questions like, "Show which product lines had the highest material waste last quarter?" for immediate insights based on smart algorithms.

- Financial-operational alignment: Connect shop floor metrics directly to income statement (P&L) impact for true costing visibility.

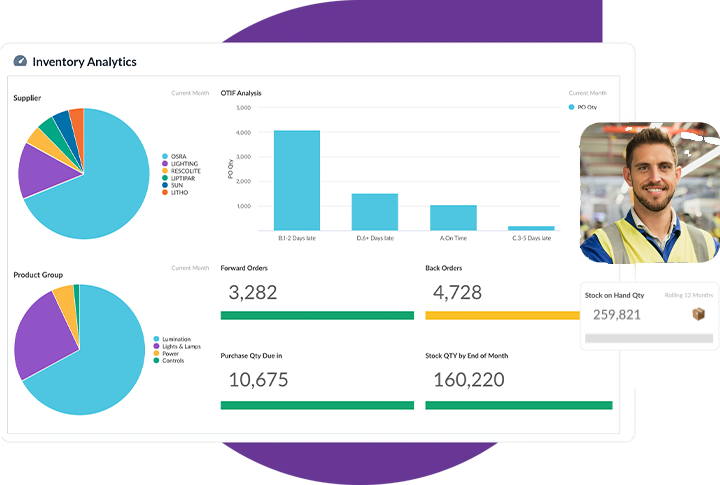

Tariff & supply chain uncertainty

Global trade tensions and shifting tariffs have introduced significant unpredictability into manufacturing supply chains. U.S. tariffs on imports like steel and aluminium have been raised or reversed with little warning, forcing many manufacturers to reevaluate sourcing strategies and pricing models.

Phocas helps you be more proactive:

- Consolidated data: Get clear operational visibility by pulling all data sources (ERPs, spreadsheets, inventory, purchasing, production, financial) into one easily accessible analytics platform.

- Supply chain optimization: Identify which products and regions face the highest tariff risks to prioritize alternative sourcing strategies.

- Forecast smarter: Use Phocas Budgets & Forecasts to model best-case, worst-case and most likely tariff or cost scenarios across products, suppliers and regions.

- React quickly: Use AI-assisted business intelligence to surface risks and supply chain gaps before they impact production.

Scale faster with Phocas

When growth demanded more from the finance team, US manufacturer IMMY chose Phocas over additional hires. The result? Faster reporting, streamlined divisional budgets and confident data-driven decisions powered by predictive analytics – like acquiring another company and restructuring departments.

Integrated with Infor CloudSuite, Phocas helps IMMY move fast with accurate, consolidated data, live budgets and powerful scenario planning.

Customer quote

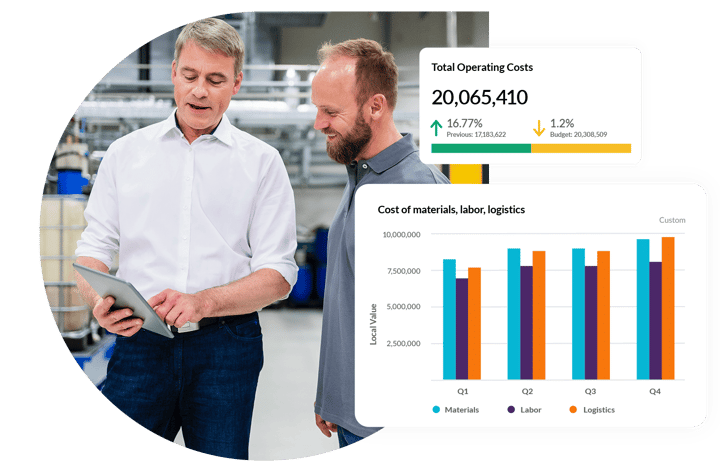

Rising costs & margin pressure

Energy, raw materials and labor costs are on the rise, and showing no signs of stabilizing. These costs are squeezing already thin margins.

With Phocas, you can:

- Analyze margins in real time: gain visibility into product, customer and regional profitability.

- Compare costs to budgets: Surface bottlenecks and inefficiencies in departmental expenses and compare against forecasts to identify variances.

- Visualize financial performance: Use intuitive dashboards that non-finance users can create, customize and explore with ease.

- Automated rebate management: Ensure that deals and discounts don't erode profitability.

Customer quote

"We now have the granularity of reporting to pinpoint the root causes of variances and performance issues. When we spot a trend, we action it immediately. There’s a huge ROI on that."

Labor shortages & production efficiency

An aging workforce and competition from other sectors are creating critical skills gaps, affecting productivity and operational KPIs across the manufacturing industry.

Phocas streamlines workforce planning:

- Headcount planning: Align workforce budgets with production targets to ensure factory floors are properly staffed.

- Scenario modeling: Visualize the impact of retirements, wage adjustments and recruitment plans on production capacity.

- Performance analytics: Compare productivity metrics across shifts, production lines and sites to optimize labor allocation.

- Waste tracking: Monitor scrap, water, energy and downtime to reduce waste and improve operational efficiency.

- Self-serve insights: Empower shop floor supervisors to explore data with intuitive, self-serve dashboards and reports.

Customer quote

"Phocas allows us to link staffing levels to productivity and machine running time. It helps us to explain the why across the production floor."

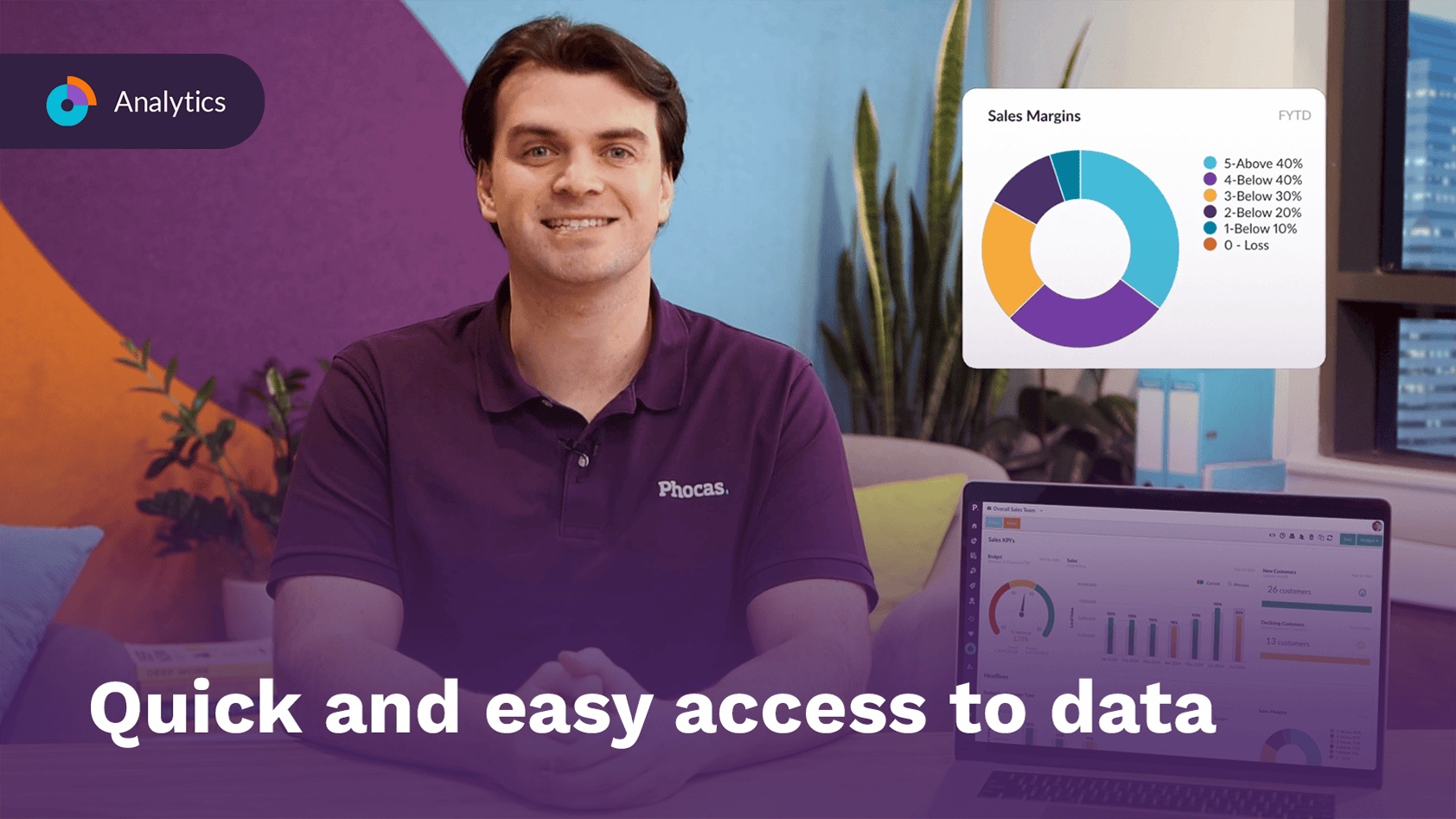

Take a Phocas product tour

-

Analytics

Analytics -

Financial Statements

Financial Statements -

Budgets & Forecasts

Budgets & Forecasts -

Platform

Platform

Evolving products & customer demand

Manufacturers must diversify product lines and meet changing customer expectations. For example, the demand for sustainable materials and electric vehicle (EV) components has surged, requiring manufacturers to adjust their product offerings and production strategies to stay competitive.

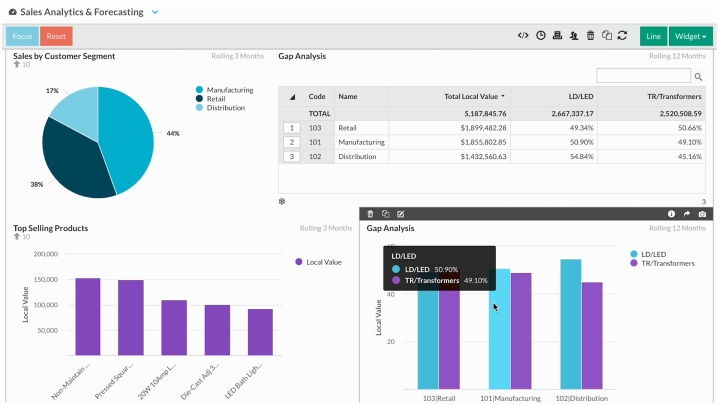

Phocas makes performance tracking quick and easy:

- Data-driven decisions: Analyze product-level margins to identify which new product lines deliver the best ROI.

- Customer adoption tracking: Drill into sales data to see which customer segments are embracing new product lines fastest.

- Production planning: Compare actual production and sales against forecasts to optimize material procurement and manufacturing capacity.

- Demand forecasting: Use real-time dashboards to identify emerging demand patterns and quickly adjust production schedules.

Navigating AI hype

AI is everywhere – but for manufacturers, all that 'AI-powered' noise can create more confusion than clarity. Phocas cuts through the hype with practical AI, purpose-built for manufacturing. Grounded in a solid data foundation, in-depth industry knowledge and decades of customer partnerships, our AI tools are designed to solve real problems across planning, production and finance – from our existing natural language query tool to the expanding roadmap of user-friendly solutions in our Phocas AI vision.

Phocas brings clarity to AI:

- Industry-specific AI: Designed for how manufacturers plan, produce and analyze.

- Explainable answers: get instant insights with full transparency – no black boxes or hallucinations.

- Future-ready tools: Tap into a roadmap of AI Agents, automated inputs, sector-trained LLMs and Open AI – built on data you already trust.

Customer quote

"We want everyone to proactively monitor the data that effects their role and to find out what’s really driving certain situations. Availability and demand changes quickly. So, data insights allow us to be nimbler. It supports us in being able to move quickly and make informed choices.”

One platform for smarter manufacturing

FP&A built on BI

What sets Phocas apart is its uniquely integrated platform that brings BI and FP&A together. Helping manufacturing businesses transform raw production, sales and financial data into actionable insights that drive better decision-making.

Phocas

Anaplan

Board

Prophix

Vena

Customer testimonials

Customer quote

“My favorite feature of Phocas is not a feature, is actually the overall flexibility of the product, you can slice and dice your sales any way that you want.”

Commercial Director

CQR

Customer quote

"Phocas drives the sales process. It identifies products that aren’t moving, where we need to start specialing items and where we’re not performing."Chief Financial Officer

JAS Oceania

Customer quote

"I would recommend Phocas for the time saving and the cost-saving. Whichever way you look, there is a benefit. Worth its weight in gold."

UK Sales Manager

Shaftec

Top KPIs every manufacturer should know and measure

Whether you're grappling with rising operating costs, managing a multi-site operation, or looking to improve forecast accuracy, this guide shows you how data can give your team the visibility and clarity to act decisively.

Download nowUnderstand the past, operate better today, and plan well for the future